In Part I of this article I talked about new ideas and advanced concepts relating to barrels and iron sights. In Part II the receiver was looked at in detail and I delved into the parts of the traditional lock: receiver, magazine and trigger, with some aside comments on ‘minor’ points such as lubrication, rear sights, and bolt handle knob, etc., although it may be argued that there are no points concerning a dangerous game rifle that could be termed as minor. Here, in Part III, I will look at several factors in building a stock for a dangerous game rifle (DGR) that would be appropriate for hunting in any climate and terrain on Earth, from the Arctic to the Tropics.

In Part I of this article I talked about new ideas and advanced concepts relating to barrels and iron sights. In Part II the receiver was looked at in detail and I delved into the parts of the traditional lock: receiver, magazine and trigger, with some aside comments on ‘minor’ points such as lubrication, rear sights, and bolt handle knob, etc., although it may be argued that there are no points concerning a dangerous game rifle that could be termed as minor. Here, in Part III, I will look at several factors in building a stock for a dangerous game rifle (DGR) that would be appropriate for hunting in any climate and terrain on Earth, from the Arctic to the Tropics.

My first-hand education in the importance of stock design for taming recoil in DGRs came to me by accident. My education began when my number one Zimbabwean professional hunter, Rowan Lewis, was visiting me in the States and I was showing him around my local gun and outdoor supply store, the now-defunct Bargain Barn.

After introductions, Mickey Jones, the gun department manager, said, “I just got a trade-in that might be of interest to y’all”, and walked to the back of the store.

He came back cradling a Mauser rifle in his arms. The first thing I noticed, as he handed it to me, was its 26-inch barrel – unusually long for a DGR.

But, what really grabbed my attention were the markings on the receiver; Mauser Modelo Argentino 1909, and Deutsche Waffen und Munitionsfabriken – Berlin, and then on the barrel; Flaig’s .458 Win Mag.

“How much?” I asked.

“Three hundred.” He answered.

I reached for my wallet.

Later that week I took the DMW Mauser and another .458 Winchester Magnum – a Winchester Model 70 Super Express with a 22-inch barrel to the Range with the intent of shooting them back-to-back for comparison. I noticed a considerable difference in felt recoil and wondered if the longer barrel of the Mauser was the reason it was so pleasant to shoot. The only problem the gun had was the safety didn’t work to my satisfaction.

The next day, I took the Model 70 over to my gunsmith, Ken Parker, to be re-barreled and chambered to .458 Lott and I took the Mauser along so Parker could tweak the safety. Ken needed to go down the road to pick up a coon dog puppy a friend was giving him and asked me and another customer if we could watch his shop while he went. I didn’t have anything pressing me for time so I agreed and sat the rifles up on the counter pad, vertically resting on their magazine plates with their buttstocks facing out.

I stood there for several minutes chatting with the other customer about hunting but when I glanced over at the rifles I stopped talking in mid-sentence.

“Do you see anything weird with those rifles”? I asked the other guy.

“Yeah, that Mauser has got a crooked stock”. This started a spirited conversation between us, and as we inspected the rifle, it was obvious that it had been intentionally made that way.

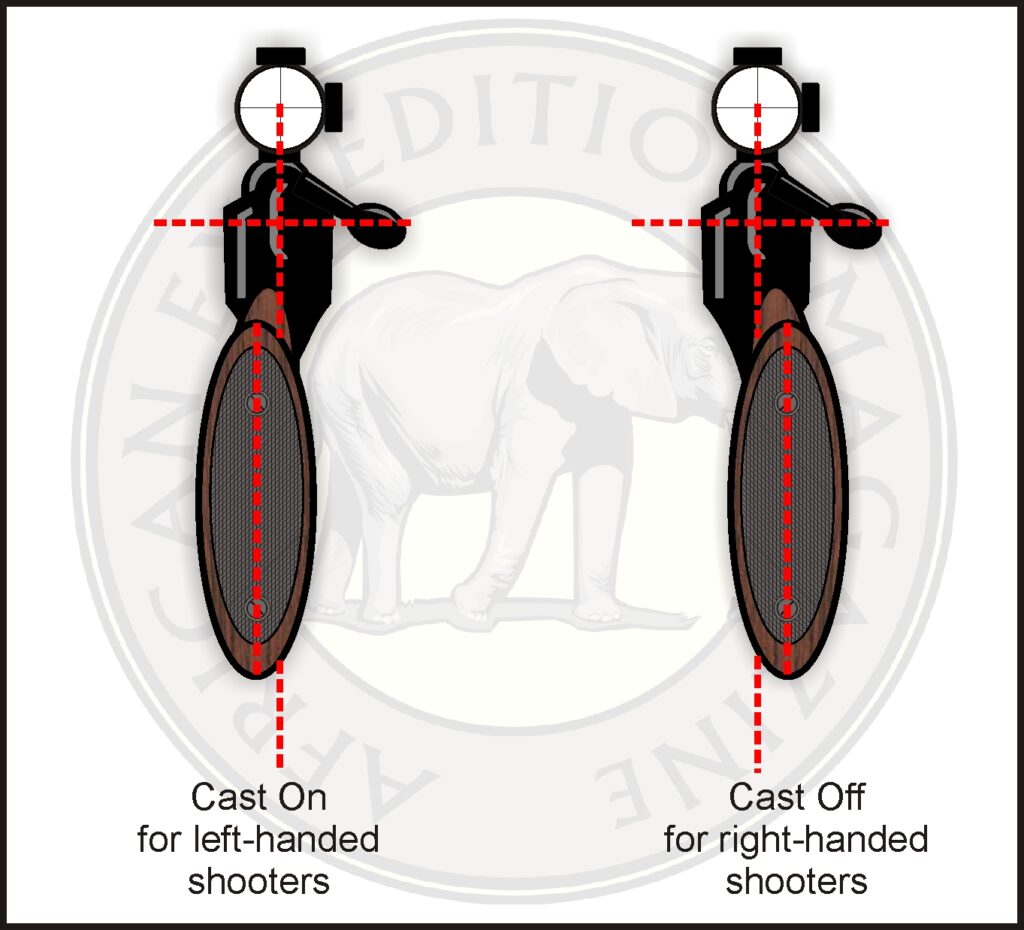

As soon as Ken returned, we showed him the “crooked” stock and asked him if he had ever seen anything like this before. He burst out laughing and asked us if we were so ignorant that we had never heard of the stock building concept of “cast off.” I had to admit that although I was pretty ignorant in general, I vaguely remembered reading something about cast off in relation to competitive shotgunning; however, I had never actually seen a stock with cast off.

His next comment really hit home when he asked, “Did you notice any difference in its kick compared to the Model 70?” I had to allow that, yes indeed, there was a hell of a big difference between the two rifles and I had the sore shoulder to prove it! This conversation was quite a revelation for me. My only assumption about cast-off was that it was something that could push up your score in skeet or trap shooting. I had no idea that it could have such a profound effect in taming the recoil of a heavy-caliber rifle.

It is no wonder that this fact had not entered my consciousness, since I had never fired a custom-stocked rifle until the day I pulled the trigger on the Flaig-built Mauser DGR.

What Cast Off Really Is

The key to proper cast off (or ‘cast in’ if you are left-handed) is to create a stock for the individual so that the rifle fits the shooter like a glove. In fact, cast-off is but one part of the equation that takes into consideration the shooter’s arm length and body type. There are several facets to this equation that I won’t get into now, however it is a topic that will be dealt with in a future article.

One key point that differentiates the stock of a DGR from the ‘garden variety’ hunting rifle is the addition of a steel cross bolt behind the recoil lug of the action. This recoil cross bolt is placed into the stock by the builder to keep the force of the recoil from splitting the stock by spreading the force of the recoil and keeping its point of greatest impact to steel on steel, rather than steel on wood. In the heaviest recoiling calibers, stock makers even install a second bolt to further dissipate recoil forces.

Another area of discussion among rifle builders is what material is the best to use for DGR stocks. It is common knowledge that a traditional, solid wood stock will warp in a climate that has very different temperatures or humidity from your home territory.

f course, this plays hell with your accuracy and can damage your stock. Here in the US, we have very hot and dry deserts in the Southwest and extremely wet and cold climates in the Pacific Northwest, especially the Alaskan region. When you throw in international destinations, it is the same situation, except the loss of time and money from warped or broken stocks, is exponentially worse in lost money and hunting opportunities!

For these reasons, many stock makers and hunters have jumped into the synthetic stock business. Although synthetics won’t warp, they do have several undesirable traits. They can be broken easily, which is why the better quality new synthetics are reinforced with Kevlar. They are also noisy when you hit a limb or rock, producing an unnatural noise that easily alerts the game. They are cold to the touch in chilly weather and relay this cold to your hands and body. They can be slippery when wet. All in all, they just don’t have a proper feel to them if your hunting experience is using wood stocks. Finally, they can’t be easily had with the correct cast-off or cast-in built into the stock for proper fit and recoil reduction. One solution to these problems is to keep the advantages of wood and merge them with the advantages of synthetics; to that end, the shooting industry developed laminates similar to the ones pioneered by the Mauser 98K rifles of WWII. Two problems emerged with laminates: First, the cheap ones with improper adhesives and sealing tended to de-laminate in bad weather or over the course of time. The second problem was of esthetics, which means they make your gun look like it is stuck into a piece of plywood.

One solution to these problems is to keep the advantages of wood and merge them with the advantages of synthetics; to that end, the shooting industry developed laminates similar to the ones pioneered by the Mauser 98K rifles of WWII. Two problems emerged with laminates: First, the cheap ones with improper adhesives and sealing tended to de-laminate in bad weather or over the course of time. The second problem was of esthetics, which means they make your gun look like it is stuck into a piece of plywood.

Accrabond Laminates was one of the first to create an esthetically pleasing laminated stock, but the founder, Mel Smart, died in 2003. However, the business was bought by Rod Rogers and Larry Tahler and is now called Serengeti Stockworks. I plan to have them restock my Brno ZKK-602, which currently is equipped with a nice, plain walnut stock; except it is a dead ringer for my plastic McMillan stocked Weatherby Mark V!

Serengeti Stockworks’ claim to fame is they will take high-grade walnut, cut it into strips, and laminate it so that it is difficult to distinguish from the original walnut. In the end, you get both the beauty of the walnut and the strength of the laminate.

A Discussion of Stocks

I have discussed laminated stocks at length with Harald Smith, the well-known gunsmith, big game hunter, and publisher of Hatari Times magazine. Here are his comments on the subject:

“I tried all sorts of laminated stuff in the past. With one brand the sheets came apart.

Another started swelling in the rainforest, much worse than a natural walnut stock. The pores of laminated wood (all layers) must be chemically sealed during the bonding process, or they will soak up humidity badly. I only found one suitable maker – even the checkering would hold on, but that company went out of business. I have not found a suitable replacement as yet.”

Every stock needs a good quality sling to aid with carrying the rifle over obstacles when you need to use both hands or just to comfortably carry the rifle while you rest your arms and shoulders. Another function a sling could fill is as a lanyard to keep the rifle attached to the hunter in the event of falling down or being knocked down by a charging animal. I recall reading in the early hunter’s journals that many times a charging animal knocked down the intrepid explorer and separated him from his rifle. That there was even a story to read indicates either the hunter or a brave tracker retrieved the rifle, and the enraged animal was finally dispatched.

Every stock needs a good quality sling to aid with carrying the rifle over obstacles when you need to use both hands or just to comfortably carry the rifle while you rest your arms and shoulders. Another function a sling could fill is as a lanyard to keep the rifle attached to the hunter in the event of falling down or being knocked down by a charging animal. I recall reading in the early hunter’s journals that many times a charging animal knocked down the intrepid explorer and separated him from his rifle. That there was even a story to read indicates either the hunter or a brave tracker retrieved the rifle, and the enraged animal was finally dispatched.

If you carefully examine pictures of US combat forces in Iraq or Afghanistan, you will see their weapons are attached to their web gear with a sling that acts as a lanyard. This is in case they fall or are knocked down; they do not become separated from their weapon. I think this would be a good thing to have on a DGR, or really any hunting rifle for use in steep or rough country. If it could also incorporate the split sling feature of the late Eric Ching’s Safari Sling design, so much the better. An often ignored role of the sling is to provide stability in shooting. The “hasty sling” which is quickly wrapping the sling in and out of the forearm supporting the rifle quickly stabilizes the rifle for an offhand, kneeling, or sitting shot.

Another new development that DGR builders could adopt from the military is the Picatinny rail. This mounting system has become the latest rage in military arms circles for mounting sights, lights, and lasers of various designs and configurations.

Standardized rail technology should be incorporated into the DGR design for the 21st century. Many of these gun designers are not thinking outside the box and keep building guns like they were building them in the first half of the 20th century. I contend that we need to keep all of the good old methods, but aggressively incorporate the good new technology whether it is CNC, EDM, Tritium, Laser, Teflon, Kevlar, or Picatinny rails.

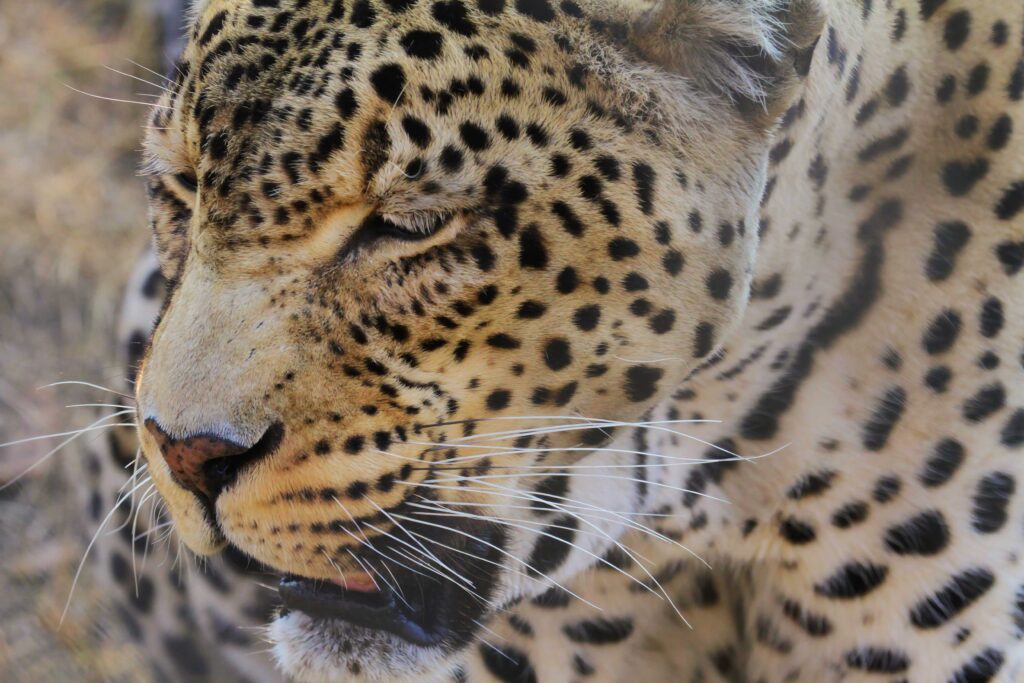

Every modern safari rifle should be fitted with a top-mount Picatinny rail system to make it easy to change scopes or swap for a red dot sight, laser sight, etc. Also, there should be a Picatinny rail extending out of the front of the fore-end to hold lights and/or laser systems when a wounded lion or leopard is being hunted (while it hunts the hunter). A small video camera, similar to what skydivers use in their helmets, could be easily installed. I am not sure today’s cameras could absorb the 5000 ft. lbs. of muzzle blast generated by a .458 Lott at 2250 fps, but if they do, I would love to have one for gun camera footage.

Every modern safari rifle should be fitted with a top-mount Picatinny rail system to make it easy to change scopes or swap for a red dot sight, laser sight, etc. Also, there should be a Picatinny rail extending out of the front of the fore-end to hold lights and/or laser systems when a wounded lion or leopard is being hunted (while it hunts the hunter). A small video camera, similar to what skydivers use in their helmets, could be easily installed. I am not sure today’s cameras could absorb the 5000 ft. lbs. of muzzle blast generated by a .458 Lott at 2250 fps, but if they do, I would love to have one for gun camera footage.

Finally, another innovative idea for stock design has come from the world of competitive shotgun shooting —a hydraulic recoil system. First seen in action on the quick-firing field artillery piece, officially known as the 75 mm Field Gun, Model of 1897, the French 75 is famous for the innovative development of its recoil system, which consisted of two hydraulic cylinders, a floating piston, a connected piston, a head of gas, and a reservoir of oil, which made for a soft, smooth operation. The French 75 was used as late as 1941 in the Philippines during World War II against the Japanese as well as in North Africa against the Germans.

Stocks, whether for a DGR, American big game, or just aesthetics, in the end, are often a personal choice and the discussion can easily go back and forth over the details until you find yourself foaming at the mouth. In the end, the market will probably make the decision for you by deciding what is available, whether it is an aftermarket stock or what is included on the new DGR out of the box.

What happens after you open the box is between you, your shoulder, your gunsmith and your wallet.

-

Krieger Barrels

2024 Mayfield Road

Richfield, WI 53076

(262) 628-8558 -

Meprolight

58 Hazait Street

P.O. Box 26

Or-Akiva, 30600 Israel

(972) 4 6244111 -

Ameriglow

5579B Chamblee Dunwoody Road, Suite 214

Atlanta, Georgia 30338

(770)390-0554. -

Trijicon

49385 Shafer Avenue

P.O. Box 930059

Wixom, MI 48393 USA

1-800-338-0563

(248) 960-7700 -

Talley

9183 Old Number Six Hwy.

P.O. Box 369

Santee, SC 29142

(803) 854-5700 -

Warne

9500 SW Tualatin Road

Tualatin, OR 97062

1-800-683-5590

(503) 657-5590 -

Robar

21438 North 7th Ave, Suite B

Phoenix, Arizona 85027

(623) 581-2648 -

New England Custom Guns

438 Willow Brook Road

Plainfield, NH 03781

(603) 469-3450