With the falling value of the Rand against the US dollar, the cost of imported archery goods continues to rise. You could almost pay for a small car (a VW Beetle or Leyland Mini) 40 years ago for what you now can expect to pay for a good quality pack of broadheads. You are looking at from R650 upwards for a pack of 3 broadheads.

So, considering the cost of between R200 – R300 per broadhead, it makes good economic sense to look after and maintain them so that they can have a maximum life. Another aspect we will look at in this article is the sharpening of broadheads and why sharp broadheads are so important. For the purposes of this article, the term “broadhead” will include fixed blades as well as mechanical broadheads.

GENERAL MAINTENANCE

Physical damage through falling, being shot into something, rubbing against other objects, and rust are the main sources of damage that can occur to a broadhead which can render it less effective or in extreme cases useless for further hunting purposes.

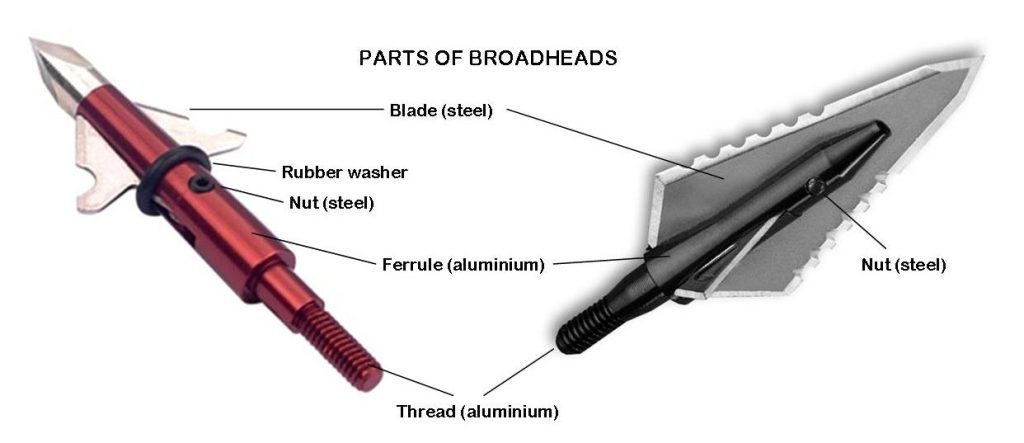

The materials of which a broadhead is made are aircraft grade aluminium (ferrule), steel (blades, nuts, and washers), and in some cases “O” ring washers to keep the blades from working loose in the arrow insert or to keep the folding blades of mechanical broadheads closed (in some models) (Figure 1)

Aluminium parts generally require the least amount of maintenance as aluminium does not rust (but can corrode if exposed to certain chemicals and moisture). Keep these parts clean, dry, and lightly oiled.

Broadhead blades are made of steel and even stainless steel can rust so for a start it is recommended that you spray all your broadheads – especially those not in use or in storage – with a good penetrating oil. For years I have used the product called “Spark” on my firearms, broadheads, and anything else I do not want to rust (Figure 2).

Be sure to store your broadheads in a cool, dry place. The higher the humidity in the place you store your broadheads the more likely they are to rust. If you live near the coast, higher humidity and more salt in the air will cause a major problem with rust. In these areas place some form of desiccant (a compound that absorbs moisture) such as silica gel sachets inside the container in which you store your broadheads.

Speaking of salt: If you have shot an animal your broadhead will have blood on it (Figure 3). If you are of a mind to re-use the broadhead wash the blood off it as soon as you can with water as blood has a high salt content which will initiate and accelerate the rusting process. Spray thereafter with a good penetrating/rust inhibiting oil. If you find a spot of rust on a broadhead blade spray a little Spark penetrating oil onto it, let it stand for a few minutes, then scrub the rust off with fine steel wool.

Heat tends to soften “O” rings and make them fragile so make sure if your broadhead has rubber “O” rings to store them in a place where they are not exposed to heat.

When practicing for a hunt use only one broadhead out of a pack. Keep the others aside for the hunt so that when they are used they are in pristine condition.

When packing, storing, transporting, or hunting, broadheads should be protected and not be allowed to move around in a bow bag or container as this will quickly dull the blades (Figure 4).

A quiver with a broadhead cover is recommended for hunting.

Prevent damage to the ferrule insert threads. If they are damaged you may experience difficulty screwing the broadhead into the arrow shaft insert. If the threads have been damaged use a thread cutter of the correct size to recut the thread or use a small needle file to touch them up. When attaching broadheads to the arrow shaft place a bit of wax on the threads. This will prevent corrosion between the aluminium threads of the broadhead and insert which sometimes causes the parts to fuse, but will also prevent the broadhead from coming loose.

WHY BROADHEADS SHOULD BE SHARP

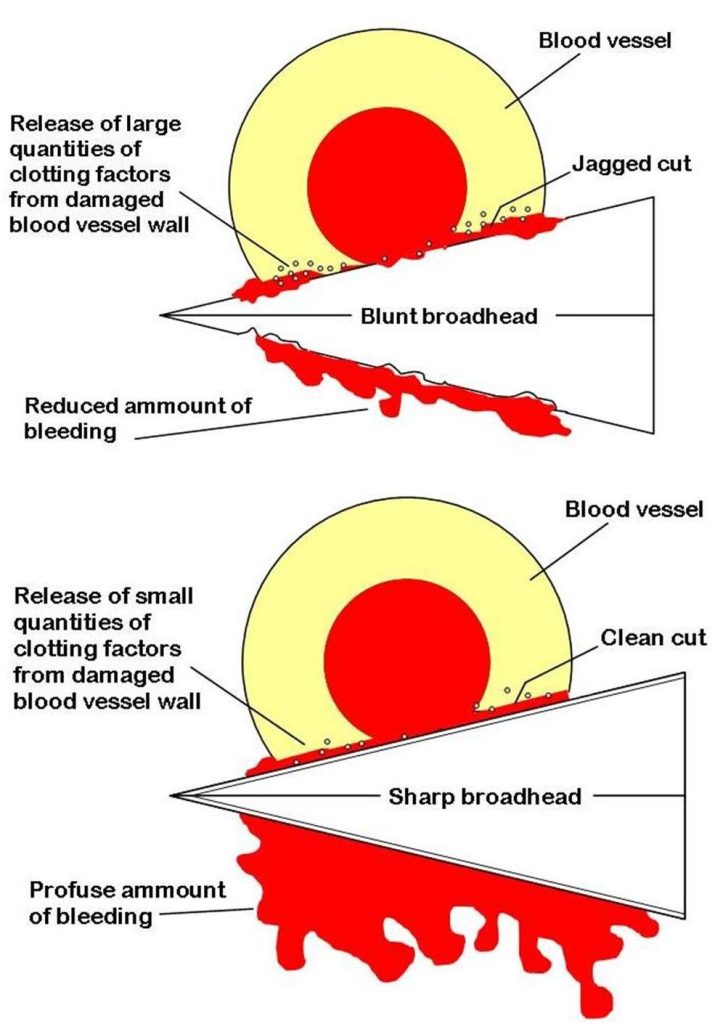

The main reason a hunting broadhead should be sharp is that it must be effective in causing massive haemorrhage so that the animal dies quickly and with a minimum of suffering. A blunt broadhead causes a ragged cut as it passes through blood vessels. This type of wound results in the release of large amounts of clotting factors from damaged blood vessel walls which promotes clotting and therefore reduces the rate of blood loss.

A sharp broadhead causes a clean cut which releases far less clotting factors and the wound bleeds profusely (See Figure 5). Rapid and profuse blood loss will cause blood pressure to drop, unconsciousness, and a relatively quick death.

SHARPENING BROADHEADS

There are three categories of broadhead sharpening:

Edge maintenance: Edge maintenance is dressing an already sharpened or formed edge with a leather strop embedded with a honing or stropping compound. “Stropping is sharpening “but does not remove metal aggressively. Using a strop instead of a stone eliminates bevel angle change and when done properly makes the extremely sharp. Stropping the broadhead each day while hunting will ensure that your broadhead will be ready when “the moment of truth” time arrives.

Bench sharpening: bench sharpening means sharpening a broadhead with a damaged or extremely dull edge. This type of sharpening is done with a sharpening tool which will remove metal while still maintaining the correct degree cutting angle. Sharpening tools for this type of operation would probably not be taken to the field but used at home on the shop bench or kitchen table.

Field sharpening: To keep broadheads” hunt ready” they should be touched up daily even if they are being carried in a quiver. This is normally done with a file or a strop.

Principle of sharpening

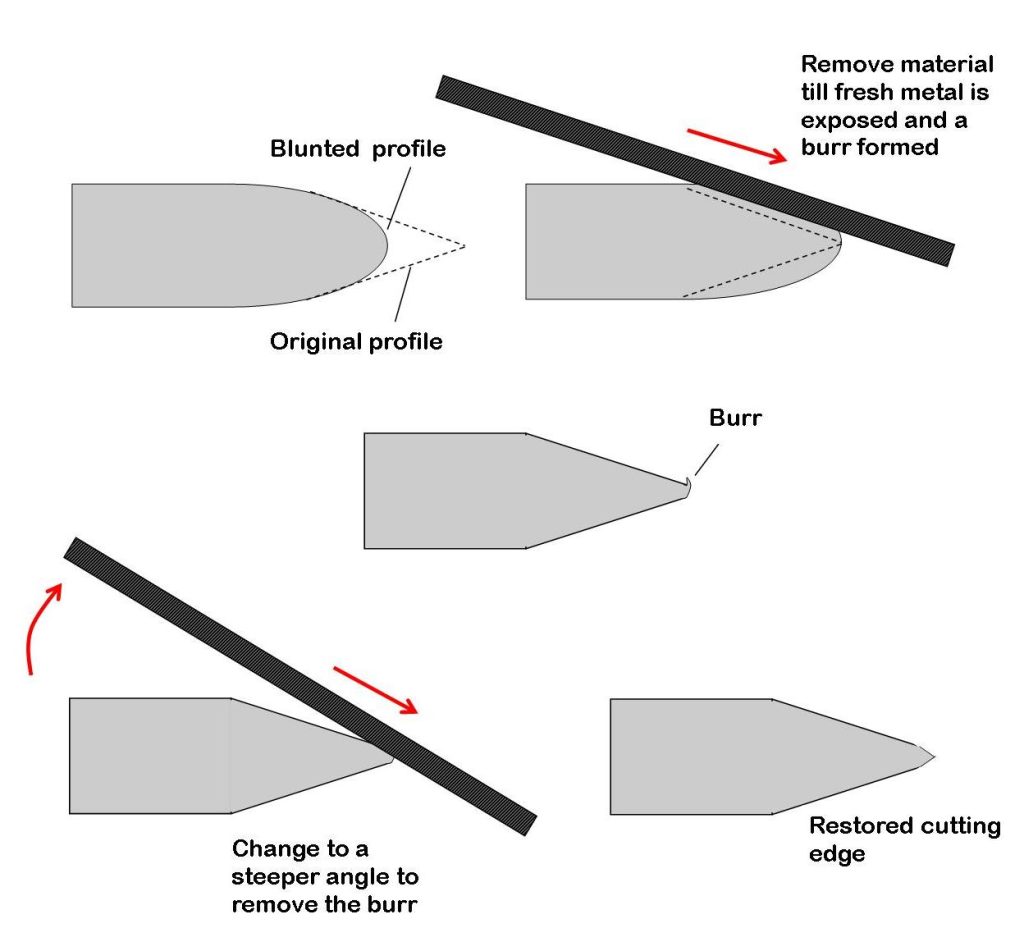

Techniques differ, but the principle of sharpening remains the same. What happens when a blade gets blunt is the sharp edge gets rounded or nicked. To restore the edge, material must be removed until you get down to a fresh edge. The secret of sharpening is very simple. You put the burr on, then you take the burr off. A burr confers two pieces of information to you. First, it informs you that you have removed sufficient metal to have arrived at a fresh edge and, secondly, that the new edge lies just under the burr.

Put the burr on, take the burr off and you will have a new sharp edge (Figure 6).

You can tell when you’ve raised a burr by feeling for it with your thumb or forefinger. You can also tell when it disappears this same way. You can test for sharpness (i.e., whether or not you’ve removed the burr) by laying the edge on your thumbnail and, resting its weight there, dragging it across the nail. If the edge bites the length of the blade, it’s sharp. If it skips, either the burr is still upon it, or the burr never got raised in the first place. When sharpening work from the back of the broadhead towards the front (Figure 7). The angle at which blade edges are sharpened is important.

Sharpening angles

Single bevel broadheads are much easier to sharpen and are generally sharpened to an angle of 250. Double-beveled broadheads are generally sharpened to 200 on each side, giving a total of 400 for the edge. The larger the angle, the more resistant it is to becoming dull. Shallow angles are sharper but will lose the edge quicker. An angle of 22.50 provides the best compromise between sharp and durable.

Re-sharpening or replacing

The decision to re-sharpen or replace a dull blade will depend on:

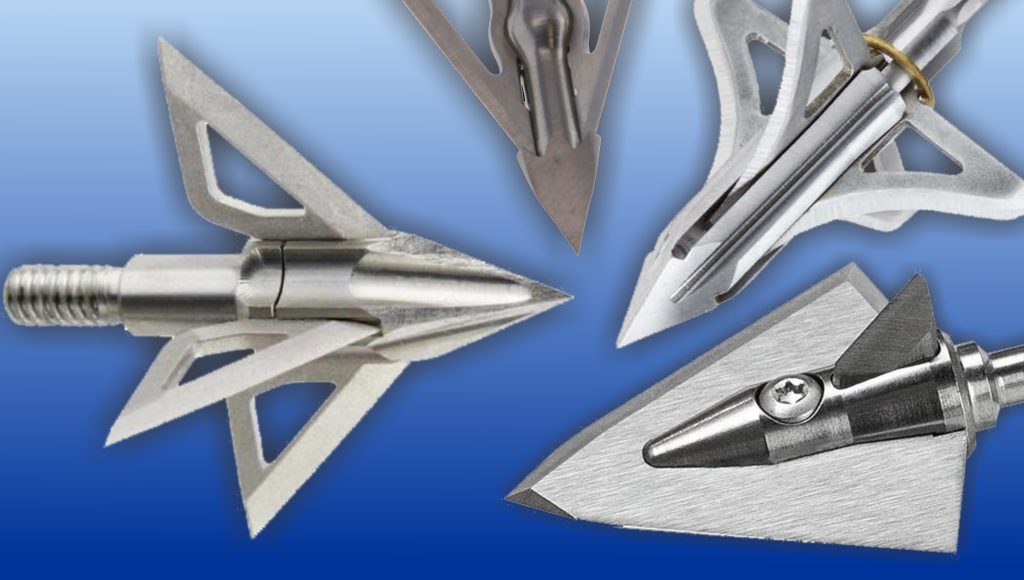

- the type of broadhead (Figure 8)

Figure 8: Types of broadheads

Fixed blade broadheads are generally easy to re-sharpen. Blades are generally replaced in replaceable blade broadheads and are not re-sharpened as the steel is usually very hard and the blades often have quite complex shapes making them difficult to re-sharpen. From an economic perspective fixed blade broadheads make good sense because they can be repeatedly re-sharpened without having to replace blades.

- the type of blade steel

Fixed blade broadheads are usually manufactured from softer steel making them easier to re-sharpen. They may not hold an edge for as long as blades that have harder steels (such as replaceable blade types) but the ease of re-sharpening is a big advantage over having to replace with a new blade.

- the shape of the blade

Blades with straight edges or with gentle contours are ideal for re-sharpening. The more complex the shape of the blade the harder it is to re-sharpen them.

- the amount of damage

It stands to reason that if a blade or other component of the broadhead is badly damaged the part must be replaced or the broadhead discarded in its entirety.

When replacing replaceable blades that are kept in place with small screws use some Loctite so that the screws do not work loose.

Tools for sharpening

However, when you arrive at your destination is up to you. Jigs, fixed file rigs, whetstones, buffing wheels, Lansky hones, or freehand with a file—each technique gets you there, but all have their peculiar pitfalls and inconveniences. Whetstones remove metal slowly. Consequently, many whetstone users work and work and never raise a burr in the first place.

Those who use a file often end up pushing the burr back and forth from one side of the edge to the other. In the process, they lose their filing angle, never get the burr cleaned off, and become frustrated with the amount of metal they have removed for a lack of results. Figure 9 illustrates a variety of commercially available sharpeners for broadheads.

Of all the tools on offer, a file offers the most convenience at home or in the field.

A sharp edge on a broadhead will not stay there indefinitely. Keep checking your broadheads for sharpness. When they fail the fingernail test, reestablish the edge. All it will require are a few passes with a file to recreate a slight burr on an oxidized edge, and a few more passes to remove it. Maintenance is easy with a file or a strop and can be accomplished quickly and conveniently.