This broadhead is produced by GrizzlyStik (Alaskan Bowhunting Supplies). According to the manufacturers, Ashby broadheads have split elephant ribs, completely passed through African and Asiatic buffalo and elephants, and have been used to successfully hunt more than 20 elephants and over 100 Cape and Asiatic water buffalo.

Packaging

The broadheads come safely packaged inside a sturdy brown plastic box with clear lid placed inside a sealed clear plastic container with colourful and information-packed insert.

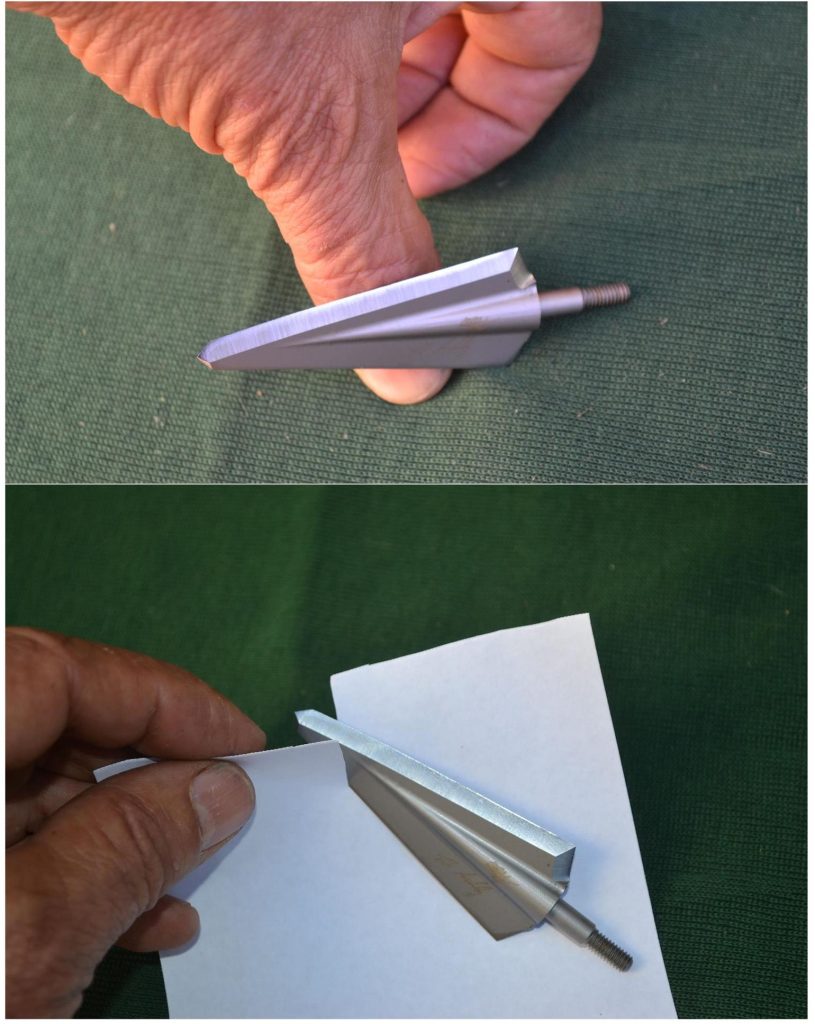

BLADE DESCRIPTION (Figure 1)

- One-piece forged construction eliminates any weak spots.

- Blades are forged from 440C cutlery grade stainless steel.

- Precision CNC machined for perfect symmetry and alignment.

- Ground with wide bone splitting 250 offset single bevels.

- All blades receive a final stropping and honing treatment to render them shaving sharp and hunting-ready straight out of the packaging.

- The point is a non-skip 300 Tanto profile.

The broadhead has a formidable mechanical advantage of 2.27.

The 3 broadheads in the package were weighed and averaged out at 315.2 grains.

Testing Method

The broadheads were mounted onto GrizzlyStik Momentum UFOC Nano 330 shafts fletched with three 2-inch plastic vanes. Total arrow weight was 861 grains and arrows had an extreme F.O.C of 28.3 %. Shaft length 30 inches. Arrows were shot from a Hoyt Spyder 70# compound bow set at 29” draw length bow kindly loaned by Magnum Archery

The broadhead is shaving sharp slices easily through paper and bites into a fingernail under its own weight. The broadhead is 2.52” long has cutting edges of 2.5” in length and a cutting width of 1.1”. Broadheads weigh in at 315 grains, have a narrow profile, non-ventilated, and are .072” thick. The ferrule fades gradually into the blade avoiding any sudden drastic and dramatic changes in profile which present an obstacle to penetration.

The broadhead was shaving sharp out of the box and passed both the paper and thumbnail test (Figure 2).

The arrows were shot out of a shooting machine into a foam target set at 20 yards to determine penetration and grouping. The grouping (3 shots) was compared to that using the same arrows but replacing the broadhead with field points of the same weight. We wanted to see how the size of grouping using field point compared to that of the broadheads and how the mean point of impact (MPI) differed without any additional tuning of the broadheads.

Another test was conducted shooting the broadhead at 20 yards through a fresh bovine scapula mounted onto a frame to ascertain its bone-penetrating capability and durability.

High-speed video footage using a state-of-the-art Metek Vision Research camera enabled us to calculate the velocity in feet per second just prior to and just after the point of impact with the scapula – a measurement far more valuable than measuring arrow velocity at the bow. From these velocity calculations, we were also able to calculate the kinetic energy and momentum of the arrow at the point of impact and as the arrow exited the scapula.

Results

Ballistics

Arrow velocity (at bow) | 215 feet per second |

Grouping (3 arrows) at 20 yards | 50 mm (1.97”) |

Deviation of broadhead MPI from field point MPI | 15 mm (low) |

Penetration into foam broadhead butt | 335 mm |

SCAPULA TEST | |

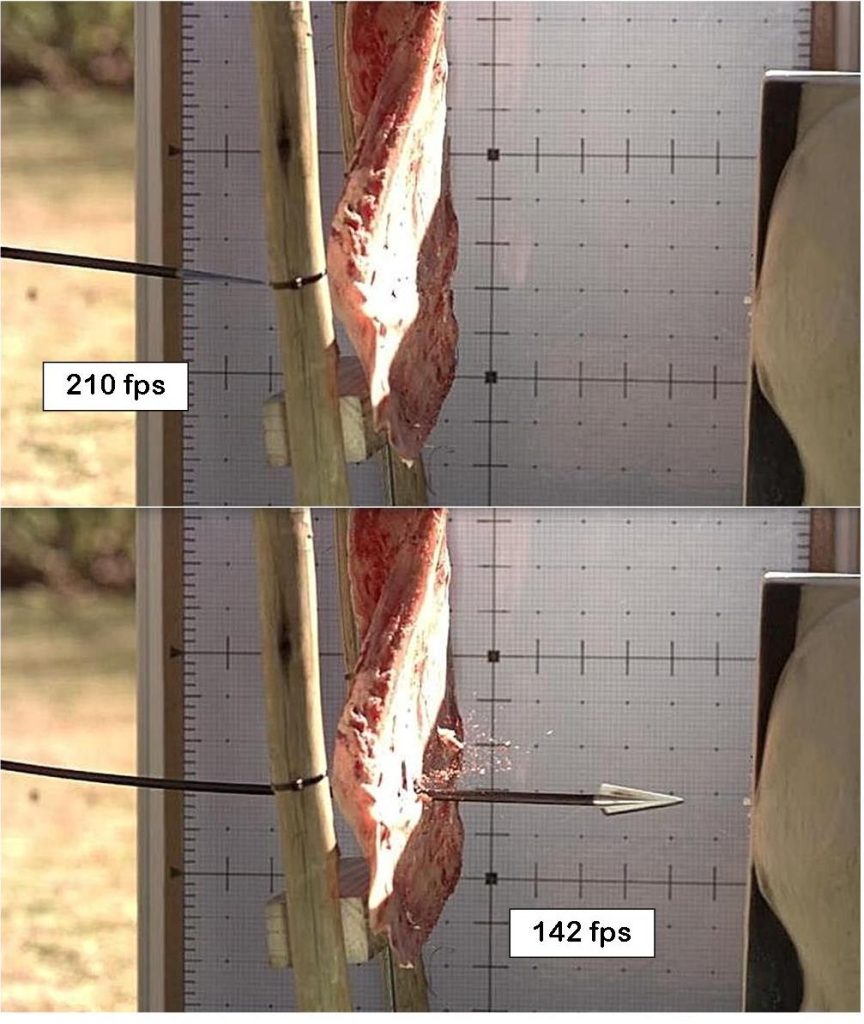

Arrow velocity at the moment of impact with scapula | 210 feet per second |

Kinetic energy at the moment of impact | 84.0 foot-pounds |

Momentum at the moment of impact | 80.0 slugs ft/sec |

Arrow velocity on exit from scapula | 142 feet per second |

Kinetic energy on exit from scapula | 38.41 foot-pounds |

Momentum on exit from scapula | 54.1 slugs ft/sec |

Loss of velocity after scapula penetration | 68 feet per second (32.4 % reduction) |

Loss of kinetic energy on exit from scapula | 45.59 foot-pounds (54.3 % reduction) |

Loss of momentum on exit from scapula | 25.9 slugs ft/sec (32.4 % reduction) |

Observations from high-speed video footage

The Ashby broadhead penetrated the thick bovine scapula with consummate ease with the arrow speed slowing from 210 feet per second just prior to impact to 142 feet per second as it exited on the far side of the scapula. The heavy arrow/broadhead combination maintained good momentum after penetration through the scapula. Figure 3.

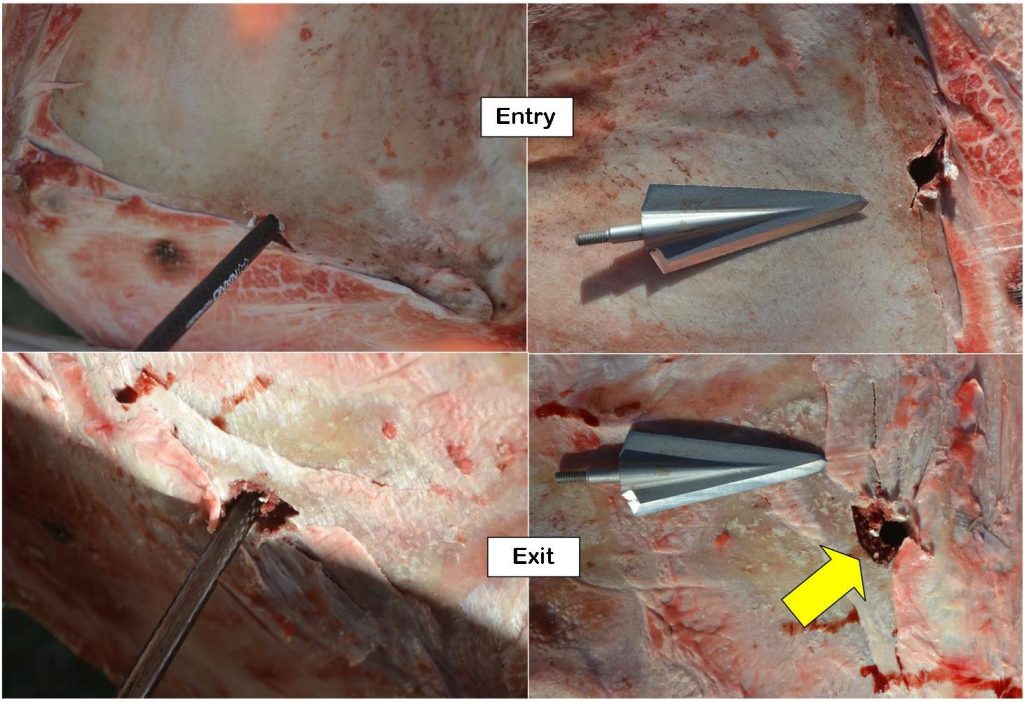

Effect on scapula

Entry into the bone was surgical and clean. The exit showed a piece of bone “blown out” as well as long cracks/fissures in the bone caused by the torque exerted by the single beveled blades. Figure 4.

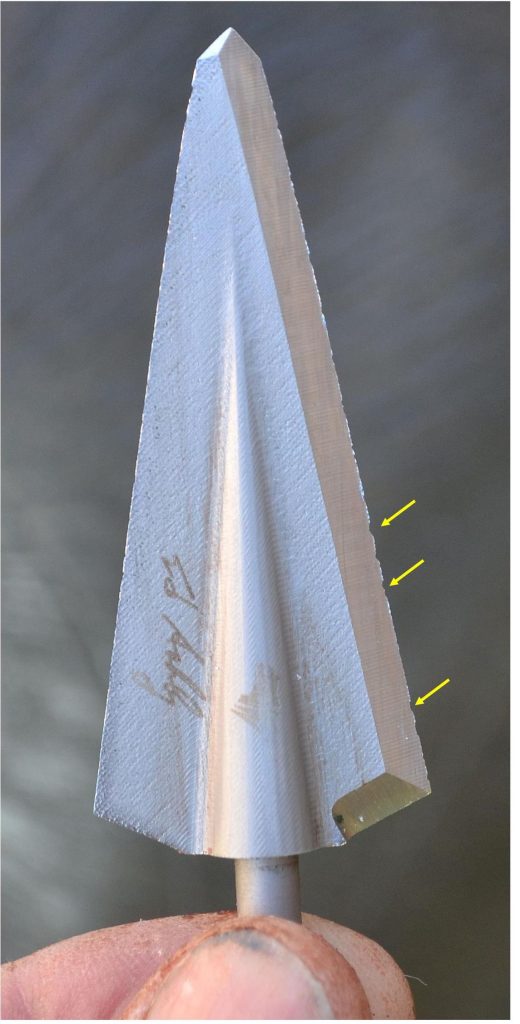

Inspection of broadhead after scapula test

After shooting through a bovine scapula the broadhead was carefully inspected for any sign of damage. Very fine serrations could be seen along the edge of the cutting surface. These were very small and could be quickly removed with a file rendering the blade useable again within minutes or in a pinch used again without re-sharpening. The Tanto point was undamaged. There was no other damage to the broadhead (Figure 5).

BROADHEAD SCORE SHEET

GrizzlyStik Ashby 315 grain fixed blade | SCORE | 1 | 2 | 3 | 4 | 5 |

Packaging and presentation | X | |||||

Mechanical Advantage | X | |||||

F.O.C | X | |||||

Cutting width | X | |||||

Cutting length | X | |||||

Blade point | X | |||||

Number of blades | X | |||||

Bevels | X | |||||

Blade thickness | X | |||||

Ferrule material and construction | X | |||||

Planing index (difference in MPI from field point MPI | X | |||||

Penetration (foam) – measured from tip of broadhead | X | |||||

Sharpness (thumbnail and paper test) | X | |||||

Strength and durability | X | |||||

Quality and value for money | X | |||||

Type of broadhead | X | |||||

Reliability of operation (moving parts) | X | |||||

Kinetic energy retention after bovine scapula penetration at 20 yards | X | |||||

Momentum retention after bovine scapula penetration at 20 yards | X | |||||

Re-useability | X | |||||

SCORE (100) | 86 | |||||

Conclusion

This is one AWESOME broadhead. If I had to choose a single broadhead to cover a range of tasks – taking small game, and birds all the way through to thick-skinned pachyderms like rhinos, hippos, buffalo, and elephants this broadhead would definitely be on my shortlist. The kinetic energy of the 858-grain arrow at a velocity of 210 feet per second was an impressive 80.28 foot-pounds. The blade has a high length-to-width ratio giving it a very high mechanical advantage and excellent penetration.

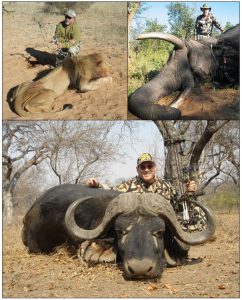

The gradual “fade in” from the cutting surfaces to the ferrule is an added “penetration enhancer”. Ribs and scapula of even big game animals will generally be penetrated by this broadhead without any trouble. It has gained a reputation for strength, reliability, and penetrating ability on plains game and dangerous big game, as examples in this article attest to. Figures 6 -9.

The forged, thick-bladed, heavy Ashby is strong and durable and with some re-sharpening of the cutting edge, could be used over and over again. I would like to see this broadhead with a bevel and a half because the only criticism I have is that whilst the single bevels are extremely sharp, the leading surfaces show slight serrations if heavy bone is hit.

This broadhead has proved itself in the field which is the best and final test for any broadhead. It is one of my favourites and one I can strongly recommend.

Thanks

Thanks to Gareth Schlieff of Alaska Bowhunting for making samples available for testing. Figures 6-9 were used with permission from GrizzlyStik.